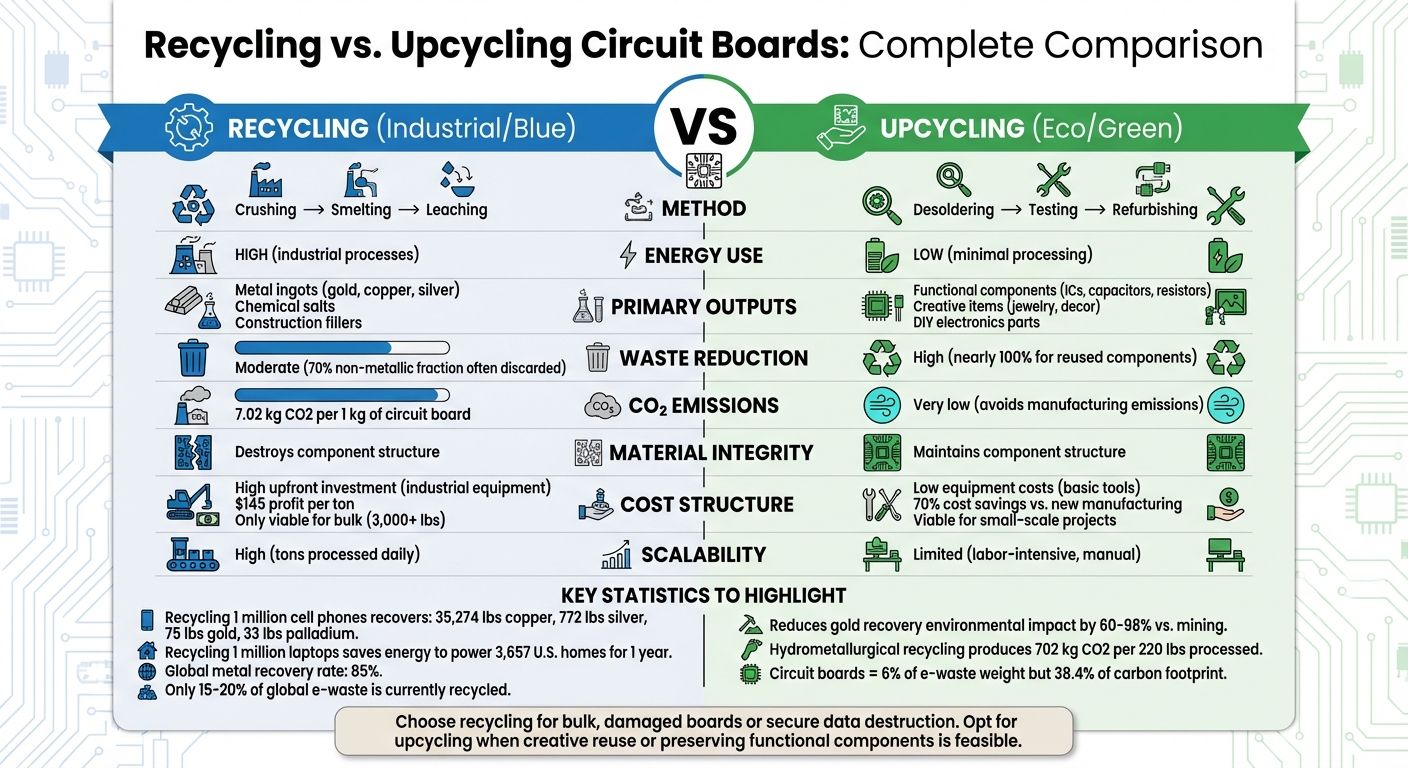

Recycling vs. Upcycling Circuit Boards

Recycling and upcycling offer two distinct ways to handle discarded circuit boards, each with unique benefits and challenges:

- Recycling: Breaks down circuit boards to recover raw materials like gold, copper, and silver. It’s ideal for large-scale disposal or damaged boards and ensures proper handling of hazardous substances.

- Upcycling: Focuses on repurposing functional components or entire boards. This method extends the life of materials, reduces waste, and creates new uses, such as jewelry or DIY electronics projects.

Key Differences:

- Recycling: High energy use; outputs include raw materials like metals.

- Upcycling: Low energy use; outputs include functional components or creative items.

Quick Comparison:

| Feature | Recycling | Upcycling |

|---|---|---|

| Method | Crushing, smelting, leaching | Desoldering, testing, refurbishing |

| Energy Use | High | Low |

| Outputs | Metals, chemical salts | Functional components, creative items |

| Waste Reduction | Moderate | High |

| Best For | Large-scale, damaged boards | Small-scale, functional boards |

Choose recycling for bulk, damaged boards or secure data destruction. Opt for upcycling when creative reuse or preserving functional components is feasible.

Recycling vs Upcycling Circuit Boards: Complete Comparison Guide

How to Recycle PCBs: From E-Waste to Valuable Materials

What is Circuit Board Recycling?

Circuit board recycling is the process of breaking down printed circuit boards (PCBs) to recover valuable materials while managing hazardous substances responsibly. Instead of letting these components pile up in landfills, recycling extracts metals like copper, gold, and palladium, returning them to manufacturing supply chains. Interestingly, the value of metals recovered from PCBs often exceeds what’s obtained through traditional ore mining.

Let’s look at the steps involved in transforming outdated circuit boards into reusable resources.

The Circuit Board Recycling Process

Recycling PCBs typically involves three main stages: pre-treatment, metal enrichment, and metal recovery.

The process begins with collection and disassembly, where PCBs are removed from their device housings. During pre-treatment, up to 90% of the components can be separated from the board, which is a critical step for effective material recovery later on.

Next is mechanical processing. Here, the boards are shredded and ground into fine particles, allowing metallic materials to be separated from plastics and ceramics. Specialized equipment like magnetic separators extract iron and nickel, while eddy current separators isolate materials like aluminum and copper.

Finally, metal recovery takes place using one of three methods:

- Pyrometallurgy: This high-temperature smelting process is used in about 70% of industrial applications.

- Hydrometallurgy: By using chemical solutions to dissolve and extract metals, this method achieves higher recovery rates while being less harmful to the environment.

- Biometallurgy: A slower but eco-friendly approach that uses microorganisms to extract metals.

Globally, these methods achieve metal recovery rates of around 85%. Together, these steps highlight how recycling turns waste into resources while minimizing environmental damage.

Benefits of Circuit Board Recycling

The benefits of recycling PCBs go far beyond simply reducing the problems of electronic waste. For instance, recycling one million cell phones can recover 35,274 lbs of copper, 772 lbs of silver, 75 lbs of gold, and 33 lbs of palladium. These materials are then reintroduced into manufacturing, cutting down the need for mining and saving significant energy. To put it in perspective, recycling one million laptops saves enough energy to power 3,657 U.S. homes for a year.

Another critical advantage is the safe management of hazardous materials. Proper recycling prevents toxic substances from contaminating groundwater or releasing harmful emissions during improper disposal. This is especially vital considering that only 15–20% of global e-waste is currently recycled.

For businesses, recycling ensures compliance with strict e-waste regulations, such as those in California, and supports the circular economy by turning discarded electronics into secondary raw materials.

"Recycling e-waste, especially PCBs, provides a route for economical and profitable extraction of valuable metals other than mining." – ScienceDirect

What is Circuit Board Upcycling?

Circuit board upcycling takes a different approach compared to traditional recycling. Instead of breaking down components into raw materials, upcycling focuses on repurposing functional parts, extending their life and creating higher-value products. Often referred to as remanufacturing or valorization, this method keeps materials in circulation longer and can result in items that are worth more than the raw metals recovered through conventional recycling.

Timing plays a key role here. Many electronic components are still in their prime when devices are discarded. For example, capacitors, resistors, and integrated circuits often remain fully functional even when the devices housing them become obsolete. Upcycling taps into this overlooked potential.

"Reuse is always considered preferable to material recovery in the waste hierarchy." – Guangming Li, College of Environmental Science and Engineering, Tongji University

Upcycling doesn’t stop at salvaging components - it also breathes new life into entire circuit boards. The intricate designs of PCBs, which resemble tiny cityscapes, inspire creative reuse in items like jewelry, coasters, and wall art. Additionally, non-metallic parts of the boards, which make up about 70% of their weight, can be transformed into advanced materials such as catalysts, nanopowders, or composites.

This shift from simply dismantling for recycling to disassembling for remanufacturing marks a growing trend in managing electronic waste. With global e-waste projected to hit 74.7 million metric tons by 2030, upcycling offers a way to reduce the demand for new manufacturing while avoiding the harmful emissions and waste byproducts associated with traditional recycling methods. Now, let’s dive into how discarded boards are turned into innovative products.

The Circuit Board Upcycling Process

The upcycling process starts with careful disassembly, using manual tools or controlled heating to melt solder without damaging components. Once removed, parts like LEDs, capacitors, and connectors are tested to ensure they meet electrical standards for reuse. These components can then find new life in DIY electronics projects, Arduino platforms, or robotics kits built from older printer circuitry.

The transformation phase varies depending on the intended outcome. In functional upcycling, components might be used to create custom breakout boards or structural housings for devices like clocks or gaming consoles. For artistic purposes, the green solder mask is often stripped away - using sandpaper or rotary tools - to reveal the intricate copper patterns underneath. These patterns can then be incorporated into tech-inspired furniture or decorative items. Educational institutions also find value in old motherboards, using them as soldering practice boards or teaching tools in computer science classes.

Benefits of Circuit Board Upcycling

Upcycling circuit boards provides both environmental and economic advantages. From an environmental perspective, it significantly reduces the carbon footprint. For instance, traditional hydrometallurgical recycling of PCBs can produce up to 702 kg of CO₂ equivalent for every 220 pounds of material processed. By reusing components, upcycling avoids this energy-intensive process and preserves the resources initially invested in the electronics. In fact, reusing components can cut the environmental impact of gold recovery by 60% to 98% compared to mining and chemical extraction methods.

Economically, upcycling creates opportunities to generate higher-value products. Instead of selling raw metals at unpredictable commodity prices, upcycled items like functional art pieces or working prototypes can command much higher market prices. A salvaged circuit board, for example, might become a unique piece of decor or a functional tool, offering far more value than its raw material equivalent.

Upcycling also supports the circular economy by keeping materials in use longer. This concept, sometimes referred to as "laddering", involves repurposing PCBs from high-end electronics for simpler applications, such as high-tech toys. It’s a way to extend the lifespan of components, reducing waste and promoting sustainability.

For businesses and organizations, upcycling offers more than just cost savings and a smaller carbon footprint. It opens up opportunities for community involvement through repair workshops and maker spaces, where discarded boards become a source of inspiration and raw materials for creative projects. From motors to switches, these components fuel innovation while fostering a sense of community and resourcefulness.

Process Differences: Recycling vs. Upcycling

Recycling and upcycling take fundamentally different approaches when it comes to handling circuit boards. Electronics recycling breaks down boards through mechanical, chemical, or thermal processes to extract raw materials. In contrast, upcycling focuses on preserving functional parts, giving them a chance at a second life through creative reuse.

Recycling involves crushing and grinding circuit boards, followed by treatments like smelting or acid leaching to separate valuable elements such as gold, copper, and silver. This process, while effective at recovering raw materials, destroys the original structure of the boards. On the other hand, upcycling takes a more delicate approach, carefully desoldering and disassembling components to retain their physical integrity and functionality.

The results of these methods are vastly different. Recycling transforms circuit boards into outputs like metal ingots, chemical salts, and fillers for construction materials. Upcycling, however, produces reusable components like integrated circuits, capacitors, and resistors. Even bare boards can be repurposed, finding new uses as decorative items or as catalysts in environmentally conscious applications.

The actual processes further highlight these differences. Recycling relies on energy-intensive methods such as pyrometallurgy (high-temperature smelting), hydrometallurgy (acid leaching), or even biometallurgy to extract raw materials. Meanwhile, upcycling skips these heavy treatments, focusing instead on testing, repairing, and refurbishing components to ensure they’re ready for reuse.

| Feature | Recycling | Upcycling |

|---|---|---|

| Method | Crushing, smelting, acid leaching | Desoldering, testing, refurbishment |

| Material Integrity | Destroys component structure | Maintains component structure |

| Primary Output | Metal ingots, chemical salts | Functional ICs, capacitors, resistors |

| Energy Demand | High (smelting and refining) | Low (minimal processing) |

The stark contrast in these methods sets the stage for understanding their broader environmental and economic implications. For organizations managing large volumes of e-waste, professional electronics waste pick-up services can streamline the transition to these sustainable disposal methods.

Another key factor is the condition of the electronic components themselves. Many components, still operating within their prime "bath curve" of reliability, are excellent candidates for upcycling. Rather than breaking these parts down for raw materials, upcycling preserves their value. As researchers from Tongji University explain:

"Reusing 'obsolete ECs' that are far from reaching the end of their useful life will help to mitigate the excessive carbon emissions associated with the mass manufacture of components".

This perspective underscores the potential of upcycling to reduce waste and lessen the environmental burden of manufacturing new electronic components.

Environmental Impact Comparison

Now that we've explored the processing differences between recycling and upcycling, let's dive into their environmental impacts. Upcycling stands out by using significantly less energy, as it repurposes circuit boards without breaking them down into raw materials. Recycling, on the other hand, involves energy-heavy processes like mechanical separation, shredding, and smelting. Even though circuit boards make up just 6% of e-waste by weight, they are responsible for a hefty 38.4% of its carbon footprint.

A 2016 study from Greece revealed that recycling 1 kg of waste printed circuit boards could lead to a net reduction of 145 kg of CO2 equivalents (see where to recycle electronic waste to contribute to these savings) by offsetting the need for extracting new materials. However, hydrometallurgical recycling of 100 kg of circuit boards still emits around 702 kg of CO2 equivalents. Upcycling sidesteps most of these emissions by avoiding the energy-intensive production of new components.

When it comes to waste reduction, upcycling also takes the lead. While recycling does reduce waste significantly, about 70% of a circuit board’s weight - the non-metallic fraction - often ends up discarded or downcycled into low-value filler materials. Upcycling, by maintaining components in their original functional state, can nearly eliminate waste for those parts.

Experts agree that reusing functional components is key to cutting emissions. Wenting Zhao and colleagues from Tongji University emphasized this point:

"Reusing 'obsolete components' that are far from reaching the end of their useful life will help to alleviate the excessive carbon emissions caused by the mass production of ECs."

Below is a comparison of key environmental metrics for recycling and upcycling.

Environmental Impact Table

| Metric | Recycling | Upcycling |

|---|---|---|

| Energy Use | High (involves shredding, smelting, and chemical leaching) | Minimal (requires cleaning, minor modifications, or component harvesting) |

| Waste Reduction | Significant, though non-metallic fractions are often discarded | Nearly 100% for reused components |

| CO2 Emissions | Moderate to high (approx. 7.02 kg CO2 eq per 1 kg of circuit board) | Very low (avoids emissions from manufacturing new components) |

| Resource Recovery | Precious metals like gold, copper, and silver are extracted | Functional components such as ICs, resistors, and capacitors are preserved |

Recycle Electronics Responsibly

Schedule a pickup or drop off your e-waste at Rica Recycling to ensure eco-friendly, secure, and compliant electronics recycling in the Bay Area.

Schedule NowEconomic and Practical Challenges

Grasping the economic hurdles of e-waste management is key to balancing cost-efficiency with environmental goals. Recycling, for instance, demands a hefty upfront investment. Businesses need industrial shredders, separation systems, and chemical processing equipment, which can run into hundreds of thousands of dollars. On top of that, operating costs - like labor, electricity, and compliance with strict environmental regulations - add up quickly. Small-scale recycling often isn't worth the effort due to shipping expenses. While high-grade circuit boards can bring in $20.00 per pound, shipping costs typically fall on the seller, erasing profits for smaller batches. Recycling depends heavily on industrial processes, whereas upcycling trades costly equipment for manual labor.

Upcycling, on the other hand, offers a different cost structure. According to the Matric Group, refurbishing or repairing circuit boards can save around 70% of the cost compared to building a product from scratch. Equipment needs are minimal - basic tools for disassembly and testing replace the heavy machinery of recycling. But there’s a catch: upcycling is labor-intensive, requiring skilled technicians to carefully disassemble, test, and troubleshoot each component.

Recycling systems, especially automated ones, can process tons of e-waste daily. These systems recover significant amounts of copper - about 200–300 kg per ton - and yield profits of roughly $145 per ton. In contrast, upcycling is more of a hands-on, project-based approach, with each board requiring manual attention.

The value of circuit boards varies widely depending on their age and type. Dan Freed, CEO of Specialty Metals, explains:

"Modern consumer electronics generally contain little to no valuable metals... The real value lies in older industrial circuit boards."

Vintage industrial or military-grade boards from the 1980s and 1990s can command up to $100 per pound. However, this creates a frustrating paradox: only about 20% of e-waste gets recycled because it’s often cheaper to buy new products made from virgin materials than to process old electronics.

Challenges Comparison Table

| Factor | Recycling | Upcycling |

|---|---|---|

| Costs | High; requires industrial shredders, chemical baths, and separation systems | Low to moderate; relies on basic tools for disassembly and testing |

| Equipment Needs | Industrial machinery like shredders, smelting furnaces, and chemical leaching tanks | Manual tools such as desoldering stations, multimeters, and diagnostic equipment |

| Scalability | High; automated systems can handle tons of e-waste daily | Limited; depends on skilled labor for individual board testing |

| Output Value | Based on commodity prices like copper ($3.85/lb) | Offers 70% cost savings compared to new manufacturing; focuses on functional components |

| Individual Viability | Low; economically feasible only for bulk quantities (3,000+ lbs) | High; ideal for small-scale DIY projects using basic tools |

These economic differences highlight the potential for upcycling as a creative alternative, which will be explored further in the next section.

Examples of Circuit Board Upcycling Projects

Taking the concept of upcycling a step further, there are plenty of creative and practical ways to repurpose circuit boards. From art and jewelry to functional items, these projects showcase how discarded materials can find a second life. Artists, hobbyists, and even researchers are proving how upcycling can extend the usefulness of materials and reduce waste.

Jewelry and wearable art have become a favorite among upcycling enthusiasts. By cutting circuit boards into geometric shapes, polishing the copper traces, and assembling them into earrings, pendants, or cufflinks, crafters create pieces that appeal to both tech lovers and environmentally conscious consumers. The best part? You don’t need advanced tools to get started - just some cutting equipment, sandpaper, and basic jewelry-making supplies.

Home decor projects are another creative avenue. Circuit boards can be turned into unique picture frames, coasters, wall clocks, or even mosaic tabletops. Some makers go a step further by embedding circuit boards in resin to craft serving trays or desk organizers, blending functionality with artistic flair.

For those with technical skills, harvesting functional components from circuit boards is a practical option. Using heat and pliers, hobbyists carefully extract capacitors, resistors, relays, and ICs for reuse in DIY electronics, educational kits, or prototype projects. This approach not only saves money but also reduces waste by giving these components a second chance to shine.

On a more advanced level, research labs are exploring groundbreaking applications for waste circuit boards. Examples include converting them into Cu-based nanostructured alloys, SnO₂ nanopowders for gas sensors, and Cu-oxide thin films for energy-related uses. These innovations demonstrate how upcycling can result in products that match or even surpass the original material’s value.

These projects highlight how upcycling isn’t just about preserving functionality - it’s about pushing boundaries and contributing to a more sustainable future.

When to Choose Recycling Over Upcycling

Upcycling circuit boards into items like jewelry or home decor can be creative and rewarding, but recycling is often the more practical option - especially when dealing with large amounts of e-waste or severely damaged boards. The choice between recycling and upcycling usually hinges on three key factors: the condition of the boards, the volume of disposal, and your primary objective. These elements help determine the best course of action.

Recycling is the go-to solution for boards that are broken, outdated, or no longer functional. If a circuit board’s components are corroded, cracked, or too old to hold any value, upcycling simply isn’t feasible. In such cases, recycling ensures that valuable materials like gold, copper, and silver can still be recovered and reused. Even damaged boards can hold surprising material value.

The scale of disposal is another critical consideration. When organizations like schools, businesses, or other institutions retire hundreds - or even thousands - of devices at once, sorting through each board for potential upcycling isn’t practical. Industrial recycling facilities are designed to handle such large-scale e-waste efficiently, making them the logical choice for bulk disposal.

Data security is also an important factor. If a device contains sensitive information that can’t be fully erased through software, recycling offers a secure way to ensure data destruction. Certified recycling facilities use methods like shredding to permanently destroy hardware, eliminating any risk of data breaches.

Lastly, recycling is essential for managing the hazardous substances often found in circuit boards. These materials, if not handled correctly, can contaminate soil and groundwater. Certified recycling facilities are equipped to safely process these toxins, reducing environmental risks. While upcycling may be a fun and sustainable option on a smaller scale, it’s not suitable for boards containing dangerous materials unless proper safety precautions are taken. For such cases, recycling remains the safest and most responsible choice.

Rica Recycling's Landfill-Free Approach

Rica Recycling is redefining how circuit boards and electronics are disposed of with its 100% landfill-free policy. By adopting this model, the company ensures that hazardous materials like lead, mercury, cadmium, arsenic, and chromium don’t seep into groundwater or release toxic gases during thermal degradation. This not only protects the environment but also aligns with strict regulatory standards, safeguarding both communities and ecosystems.

Specializing in certified electronics recycling and IT asset recovery, Rica Recycling serves businesses, schools, and organizations across the Bay Area. Whether you need to retire a single device or an entire fleet of electronics, the company manages everything from laptops and servers to circuit boards and other electronic components. With pickup and drop-off options, they make responsible disposal simple and accessible, no matter the size or location of your organization.

Compliance and Responsible Practices

Rica Recycling operates with a strong commitment to meeting and exceeding regulatory requirements. California has some of the toughest e-waste laws in the U.S., and the company ensures full compliance with these regulations as well as EPA standards. Their practices are aligned with globally recognized certification programs like R2 (Responsible Recycling) and e-Stewards.

"Certified electronics recyclers have demonstrated through audits and other means that they continually meet specific high environmental standards and safely manage used electronics." – U.S. Environmental Protection Agency

Non-compliance with California’s DTSC regulations can result in penalties of up to $70,000 per day, while federal RCRA violations can cost as much as $37,500 per day. By partnering with Rica Recycling, organizations can avoid these costly risks while ensuring their e-waste is handled responsibly and in accordance with the law.

Services for the San Francisco Bay Area

To address the growing need for secure disposal, Rica Recycling offers secure data destruction services, ensuring sensitive information is protected during the recycling process. This is particularly vital for organizations managing confidential data such as business records, student files, or patient information. The company provides formal certificates of data destruction, giving clients peace of mind and compliance with data security regulations.

Rica Recycling also collaborates with local organizations to make e-waste disposal more accessible throughout the Bay Area. Their IT asset recovery services allow businesses and institutions to recover value from outdated equipment while staying environmentally responsible. Additionally, the company organizes community drop-off events and works with schools, nonprofits, and government agencies to simplify the process of responsible electronic waste disposal.

Conclusion

Recycling and upcycling serve distinct but equally important roles in managing electronic waste. Recycling focuses on breaking down circuit boards to recover raw materials like gold, copper, and silver, while upcycling gives functional components a second life by transforming them into new, repurposed products. Deciding between these methods depends on factors like the condition of your electronics, the volume of waste, and your environmental priorities.

"Reuse is always considered preferable to material recovery in the waste hierarchy." - Environmental Science: Advances

Both methods play a critical role in promoting a sustainable, circular economy. Upcycling reduces carbon emissions and energy consumption by extending the usability of components, whereas recycling ensures valuable materials are reclaimed, even from non-functional devices. For example, recycling one million laptops saves enough energy to power 3,657 U.S. homes for a year.

Rica Recycling exemplifies responsible e-waste management through its 100% landfill-free process. Whether you choose to recycle or upcycle, their certified services ensure secure data destruction and proper handling of your electronics. With convenient pickup options across the San Francisco Bay Area, they make it easy for businesses, schools, and organizations to take meaningful steps toward sustainability.

FAQs

How does upcycling circuit boards benefit the environment compared to recycling?

Upcycling circuit boards brings notable environmental benefits by reusing functional components rather than dismantling them completely. This approach cuts down on the energy required to produce new parts, saves precious materials like metals and polymers, and limits the release of harmful substances often linked to conventional recycling processes.

By giving existing components a second life, upcycling plays a key role in reducing electronic waste and promotes a more resource-efficient, circular system.

What does the process of upcycling circuit boards involve?

Upcycling circuit boards is all about giving old or discarded printed circuit boards (PCBs) a fresh purpose. It starts with sorting and inspecting the boards to pinpoint components that can be reused. Parts like capacitors, resistors, and integrated circuits are carefully extracted, tested to ensure they still work, and cleaned up. Once ready, these components can either be refurbished or directly incorporated into new devices, prototypes, or even educational kits.

But it doesn’t stop there. The leftover PCB material - usually a mix of fiberglass and metal - can be transformed into entirely new materials, like conductive inks, carbon fillers, or structural composites for non-electronic applications. This method not only cuts down on e-waste but also breathes new life into resources that might otherwise end up in a landfill.

For those in the San Francisco Bay Area, Rica Recycling offers certified e-waste collection and IT asset recovery services. They ensure circuit boards are handled safely and repurposed responsibly, all while adhering to California’s strict environmental regulations.

When is it better to recycle circuit boards instead of upcycling them?

Recycling is the go-to option for circuit boards that are damaged, no longer functional, or contain materials that require careful handling due to safety concerns. It’s also an effective way to recover metals like gold, silver, and copper, which can be reclaimed and repurposed in manufacturing processes.

For those managing large volumes of circuit boards or aiming to meet environmental regulations, recycling offers a responsible solution. It helps keep e-waste out of landfills and supports broader efforts to reduce waste and conserve resources.