Study: Impact of Layout Design on Recycling Efficiency

Facility layout design directly impacts how efficiently recycling plants operate. A well-thought-out layout improves material flow, reduces contamination, and increases recovery rates. Poor layouts, on the other hand, create bottlenecks, increase downtime, and lower overall productivity.

Key takeaways from the study:

- Throughput: Upgraded layouts can double material processing speeds by eliminating bottlenecks and improving flow.

- Contamination: Strategic zoning (e.g., "Dirty", "Transitional", and "Clean" areas) reduces cross-contamination and improves sorting accuracy.

- Recovery Rates: Modern layouts incorporating advanced sorting units and technologies, like optical scanners and digital watermarking, boost recovery rates by up to 16 percentage points.

- Case Studies: Facilities in the U.S., Italy, and Greece demonstrated significant efficiency gains after layout redesigns.

How Layout Design Impacts Recycling Efficiency

Impact on Throughput and Processing Speed

The design of a recycling facility's layout plays a major role in how efficiently materials flow through the system, beyond just the capacity of individual machines. Poorly designed layouts often lead to bottlenecks, such as material surges or delays at the feed throat, which slow down processing. For instance, well-planned facilities can handle 50–100 vehicles per day, while poorly designed ones may only manage 20–30.

Strategic layout choices, like adding buffer storage and carefully placing weighbridges and intake zones, help reduce congestion and speed up operations. Research using reinforcement learning for layout optimization showed promising results, including a 0.3% increase in throughput and a 3.8% reduction in logistics movement distances.

These improvements in flow and speed also pave the way for better sorting accuracy and reduced contamination.

Effect on Contamination Levels

The layout of a facility also influences sorting accuracy, as it dictates the sequence and types of separation technologies used - such as air classifiers, magnetic separators, and optical sorters. A study conducted in February 2023 at the Azienda Servizi Municipalizzati (ASM) facility in Molfetta, Italy, highlighted how traditional layouts can fail to efficiently sort certain materials. For example, weaknesses in 2D flow sorting lines led to missed small flexible packaging and biopolymers. While the facility achieved high efficiency for PET and PE bottles (80.2% and 92.8%, respectively), the efficiency for mixed flexible packaging dropped to 50–55%.

"Contamination of recyclable materials - such as food waste or non-recyclable plastics - can reduce the quality of the end product and complicate the sorting process." - Mark Vanham, Department of Mechanical Engineering, Iowa State University

Optimized layouts address these issues by incorporating modular units that isolate materials, which helps reduce cross-contamination. Facilities that zone areas into "Dirty", "Transitional", and "Clean" sections further improve sorting accuracy by preventing contamination as materials move through the process. On average, municipal recycling facilities face contamination rates between 19% and 40%, meaning about one in four items placed in recycling bins is too contaminated to be recycled.

Better sorting purity not only improves the quality of recycled materials but also enhances recovery rates.

Recovery Rates: Optimized vs. Traditional Layouts

The ASM facility study also demonstrated how upgrading layouts can significantly improve recovery rates. By adding five new sorting units to target specific materials - like non-selectable PET bottles, PET trays, small PE films, rigid PS packaging, and bioplastics - the facility increased its collectible output by over 16 percentage points. These upgrades addressed inefficiencies in the 2D sorting line, achieving 96.9% sorting efficiency for biopolymers and 87.8% for small flexible PE packaging films.

In a separate study conducted in February 2025, researchers tested a portable robotic recycling facility in Heraklion, Greece. Using a multi-robot, multi-gripper layout optimized by a novel scheduling heuristic, the system improved pick rates by up to 37.5% compared to traditional methods. Specialized grippers - such as suction, parallel, and HAVCO - enabled the system to handle diverse waste streams, including PET, PE bottles, and foils. Additionally, advanced technologies like digital watermarks have shown the potential to achieve 95% purity rates in semi-industrial trials.

These examples highlight how thoughtful layout design can transform recycling efficiency, from faster processing speeds to cleaner material recovery.

sbb-itb-855056e

The Big Sort: An Insider's Tour of a Recycling Plant

Comparing Traditional and Optimized Facility Layouts

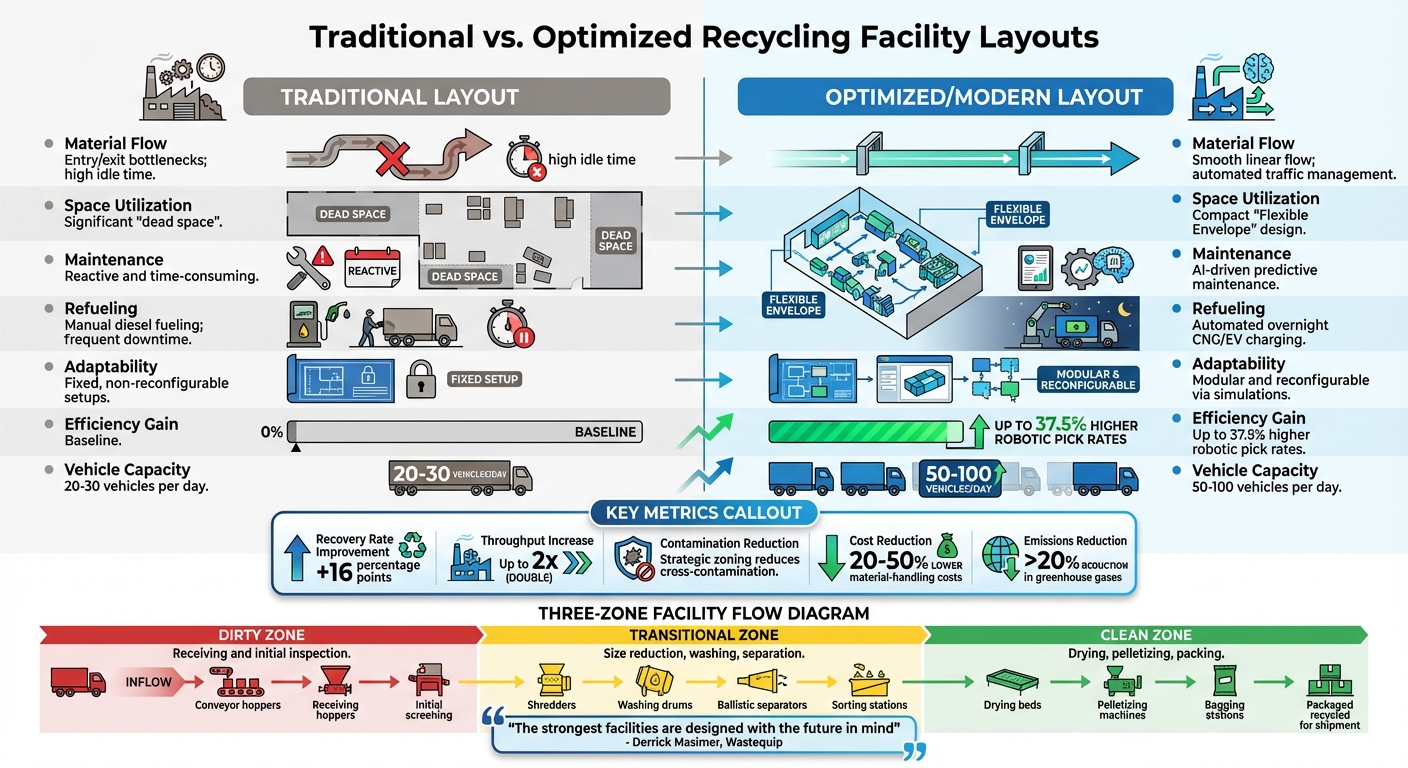

Traditional vs Optimized Recycling Facility Layout Comparison

Layout Metrics Comparison

When you look at traditional recycling facilities versus modern ones, the differences are hard to miss. Traditional layouts often struggle with bottlenecks at entry and exit points, leading to trucks sitting idle. Inside, disorganized storage areas and cramped repair spaces make it tough to run multiple operations smoothly.

On the other hand, modern layouts are built with efficiency in mind. They use compact "Flexible Envelope" designs to eliminate wasted space while maintaining the necessary dimensions for specialized equipment like sorting and cleaning units. These facilities also feature AI-driven maintenance systems and modular repair bays, which help reduce downtime. Automated overnight fueling systems, including CNG or EV charging stations, further minimize vehicle downtime.

Here's how the two approaches stack up:

| Metric | Traditional Layout | Optimized/Modern Layout |

|---|---|---|

| Material Flow | Entry/exit bottlenecks; high idle time | Smooth linear flow; automated traffic management |

| Space Utilization | Significant "dead space" | Compact "Flexible Envelope" design |

| Maintenance | Reactive and time-consuming | AI-driven predictive maintenance |

| Refueling | Manual diesel fueling; frequent downtime | Automated overnight CNG/EV charging |

| Adaptability | Fixed, non-reconfigurable setups | Modular and reconfigurable via simulations |

| Efficiency Gain | Baseline | Up to 37.5% higher robotic pick rates |

"The strongest facilities are designed with the future in mind, not just focused on today's challenges. By anticipating regulatory shifts, allowing room for technological advancements, and elevating the work conditions, facilities are better positioned to adapt without disruption." - Derrick Masimer, Vice President of Sales, Wastequip

These differences in design don’t just look good on paper - they lead to real improvements in throughput, sorting precision, and overall operational efficiency, as seen in the case studies below.

Case Study: Modern Layout Design Benefits

To see these concepts in action, let’s look at some examples. In 2024, Rumpke Waste & Recycling opened a $100 million, 223,000-square-foot facility in Columbus, Ohio, designed by Moody Nolan. This modern facility replaced outdated methods with an optimized layout, including three tipping floors covering 48,000 square feet and cutting-edge Machinex optical scanners. The result? The facility processes 60 tons per hour, allowing Columbus to increase recycling collection from every two weeks to every week. It can now handle over 250,000 tons of curbside plastics, metals, and glass annually, alongside specialized electronics recycling services.

Another example comes from Guangzhou, China, where researchers used a two-stage stochastic model to plan recycling centers that could handle uncertainties in waste supply and material demand. This approach led to a 7% increase in the total weight of construction waste recycled, all within the same investment budget, compared to traditional models. These examples highlight how well-thought-out layouts can directly boost efficiency and reduce environmental impact in real-world scenarios.

Recommendations for Improving Recycling Facility Layouts

Building on earlier insights into how layout affects operations, here are some practical strategies to improve recycling facility design and efficiency.

Designing Linear Material Flow

A well-organized recycling facility typically divides its layout into three key zones: Dirty (receiving and initial inspection), Transitional (processes like size reduction, washing, and separation), and Clean (drying, pelletizing, and packing). This separation helps prevent cross-contamination between raw materials and finished products. To maintain efficiency, buffer storage like bins and silos can be used to decouple process steps, ensuring a steady material flow even when truck arrivals or packaging schedules vary. Additionally, clear maintenance access points and designated forklift lanes are essential to minimize bottlenecks and safety hazards, especially in high-volume electronics recycling facilities.

"Recycling lines rarely fail because the core machine can't melt or cut plastic. They fail because the plant layout creates bottlenecks: poor material flow, unsafe loading zones, no buffer capacity, or auxiliary systems that don't match the feedstock."

Using Modular Sorting Stations

Modular sorting stations offer a flexible way to handle changing waste streams without the need for a complete facility redesign. Research shows that adding modular units tailored to specific materials, such as bioplastics or small flexible films, can significantly boost the amount of recyclable output. Before implementing these units, it's crucial to identify bottlenecks - whether they occur in feeding, screen changes, or packaging - so the upgrades address real operational challenges. Advanced technologies like Near-Infrared scanners and digital watermark detectors further enhance sorting precision. For instance, in semi-industrial trials involving 125,000 samples, digital watermarking modules achieved a 99% detection rate with 95% purity.

Creating Flexible Zones for Multi-Material Processing

Taking modularity a step further, flexible zones allow facilities to adapt to shifting material flows and regulatory demands. Moving away from traditional process-based layouts to value stream–focused designs connects related processes, which reduces material handling and ensures smoother operations. Data-driven layout models make it possible to reconfigure spaces as needed while maintaining efficient use of equipment and minimizing wasted areas. Features like clear traffic lanes and consistent color-coded zones can also help reduce sorting errors and contamination risks. Additionally, planning for modular repair and sorting bays ensures the facility can adapt to new material types or compliance requirements over time.

| Feature | Traditional Layout | Optimized Flexible Layout |

|---|---|---|

| Organization | Grouped by machine type (process-based) | Linked by value streams (connected processes) |

| Equipment | Large, high-volume batch machines | Smaller, adaptable machines for specific product families |

| Material Flow | Long lead times and high work-in-process inventory | Continuous flow with reduced handling and floor space |

| Space Usage | Aesthetic or simple footprints | Prioritizes functionality, minimizing unused space |

Applications for Electronics and E-Waste Recycling

Improving Recovery Rates for Electronics

Designing facilities with optimized layouts can significantly enhance the recovery of materials from electronics while minimizing contamination. By dividing the space into distinct zones - "Dirty" areas for receiving and inspections, "Transitional" zones for disassembly and size reduction, and "Clean" areas for processing recovered materials - recycling operations become more efficient.

Studies indicate that well-structured recycling systems improve eco-efficiency by 29.74%, increase economic returns by 28.96%, and cut carbon emissions by 15%. For e-waste facilities, layouts that prioritize disassembly line balancing allow for the early removal of hazardous components and the effective recovery of valuable rare-earth elements. This approach not only reduces handling times but also ensures smoother workflows, making the entire recycling process more efficient.

Reducing Handling Time and Improving Workflow

To minimize downtime, contamination, and damage, facilities should aim to reduce unnecessary inter-station transfers. A smartly designed layout aligns workstations in a logical sequence - sorting, dismantling, cleaning, testing, and packaging - mirroring the natural flow of disassembly.

"Layout drives labor, safety, and uptime - not only footprint."

- Energycle

Clear paths for forklifts and designated access points for maintenance are essential for preventing bottlenecks. When facilities account for service clearances around shredders and sorting equipment, technicians can perform maintenance without halting production. These measures lead to safer working environments, less downtime, and increased throughput. Ultimately, these workflow improvements align with broader sustainability efforts.

Supporting Rica Recycling's Landfill-Free Policy

Optimized layouts play a critical role in supporting Rica Recycling's commitment to a 100% landfill-free policy. By reducing wasted space and streamlining sorting, disassembly, and cleaning processes, facilities can recover nearly all components for reuse or recycling.

Digital watermarking technology has shown impressive results, achieving 99% detection accuracy and 95% purity in trials. This innovation can lower recyclate production costs by 30%. For a Bay Area recycling operation serving schools, businesses, and organizations, these advancements translate into tangible environmental benefits - less waste heading to landfills, reduced transportation emissions, and better compliance with California's stringent e-waste regulations.

Conclusion

Facility layout design plays a key role in improving recycling efficiency, cutting costs, and boosting environmental performance. Research indicates that well-designed layouts can lower material-handling costs by 20% to 50% and reduce greenhouse gas emissions by more than 20%. For organizations focused on sustainability, these changes support landfill-free operations and help meet strict regulatory requirements.

Older, traditional layouts often lead to wasted space, production bottlenecks, and higher costs. In contrast, modern approaches like the Flexible Envelope model eliminate unused areas and improve material flow. When paired with strategies like zoning, buffer storage, and data-driven reconfiguration, these layouts allow facilities to adapt quickly to shifting waste streams and market needs.

These benefits provide a clear path for facilities aiming to meet demanding sustainability goals. For example, e-waste recyclers in the Bay Area can align these findings with Rica Recycling's dedication to maintaining a 100% landfill-free policy while complying with California's strict environmental standards.

To achieve these outcomes, focus on identifying bottlenecks, ensuring easy maintenance access, and making layout decisions based on data. Whether designing a new facility or upgrading an existing one, investing in smart layout design is one of the most impactful steps you can take for operational efficiency and environmental responsibility.

FAQs

How does facility layout design improve recycling efficiency?

Facility layout design is a game-changer when it comes to improving recycling efficiency. It’s not just about the machines you use - it’s about how everything is arranged to streamline the flow of materials and avoid operational hiccups. Research highlights that many inefficiencies stem from poor layouts that disrupt the way materials are received, sorted, and processed.

An effective layout should clearly define spaces for incoming materials, sorting areas, and finished products. Adding buffers between these zones is another smart move, as it helps balance out differences in processing speeds, keeping everything running smoothly.

On top of that, modern tech tools like real-time data monitoring and AI-powered systems give operators the insights they need to keep things flowing. These tools allow for quick adjustments to address any issues, reduce delays, and maintain productivity. Together, these strategies ensure a more efficient recycling process from start to finish.

How does facility zoning help reduce contamination during recycling?

Facility zoning plays a crucial role in keeping contamination at bay during recycling. By carefully organizing the layout, facilities can separate different stages of the process. For instance, placing "dirty" areas like receiving and sorting far from "clean" zones where materials are handled ensures that contaminants don’t mix with clean recyclables. This setup helps maintain the quality and purity of the materials being processed.

Beyond contamination control, zoning boosts efficiency and safety. Clearly defined spaces for each recycling step make operations more streamlined and organized. This approach not only improves the overall quality of recyclables but also helps facilities meet environmental regulations, making recycling processes more effective and responsible.

How do modern facility layouts improve recycling efficiency?

Modern recycling facility layouts are crucial for boosting efficiency and cutting down waste. Studies highlight that strategic zoning, such as separating receiving and sorting areas from clean processing zones, helps avoid cross-contamination and improves workflow.

Another effective approach is adding buffers between processes that run at different speeds. These buffers help maintain a steady flow of materials, reducing delays and preventing unnecessary losses. By focusing on layouts that tackle specific bottlenecks and streamline material movement, recycling plants can recover more usable materials while improving overall operational efficiency.